Textile printing and dyeing enterprises are mainly distributed in Zhejiang, Jiangsu, Fujian, Shandong, Guangdong and other eastern coastal provinces, the industry competition pattern is more scattered. Middle and low end production capacity is generally surplus, while the supply of medium and high end products is insufficient. After 2017, the demand for environmental protection has become more stringent, environmental standards and costs have increased, resulting in the shrinkage of small and medium-sized production capacity with weak profitability. The problem of energy consumption is more serious. At present, the total energy consumption of China's textile industry accounts for 4.3% of the total industrial energy consumption of the whole country. The printing and dyeing process equipment and the boiler system which provide heat energy for them form two energy consuming giants. Dyeing, drying, sizing, printing and dyeing are inseparable from the support and cooperation of the boiler.

![]() Send Enquiry

Send Enquiry

![]() Get Quotation(contact us by one of the three ways)

Get Quotation(contact us by one of the three ways)

If you are interested in our products, please email us at [email protected]

Applicable industries: textile printing and dyeing industry scheme: rated output: 15 tons.

The main process of textile printing and dyeing is divided into three steps: pretreatment, dyeing and printing, and finishing. The main processes are singeing, desizing, boiling, bleaching, mercerizing, setting, drying and dyeing. Boiler is a member of textile production line equipment, used to drive drying equipment, and in the pressing, singeing, desizing, bleaching, setting, dyeing and other links in the heating.

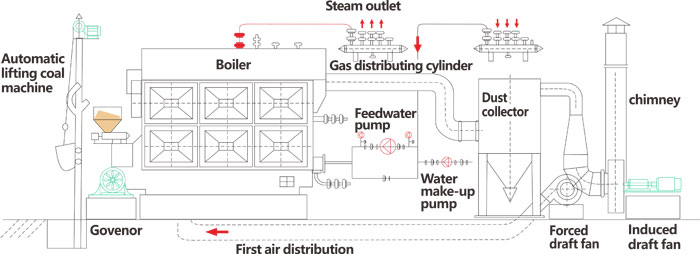

ZOZEN Boiler has served many small and medium-sized textile printing and dyeing enterprises in China, and has many years of project experience in this industry. Small and medium-sized textile mills tend to use small coal-fired steam boilers because of their high fuel consumption in the textile industry. For example, a printing and dyeing cloth production enterprise with an annual output of 30 million meters, the technical personnel of the central boiler recommended a 15 ton SZL 15-1.25-A II steam boiler.

Through the statistical analysis of ZOZEN boiler customer cases, in addition to SZL series, DZL series steam boiler use frequency is higher, along with the promotion of small-scale boiler gas substitution, there are many textile printing and dyeing enterprises will choose fast-loading structure of WNS and SZS steam boiler, combustion efficiency is extremely high, energy efficiency is also very high. Although the cost of gas fired boiler is higher, especially the cost of boiler fuel. But from the perspective of national environmental policy, energy saving and emission reduction are better.

1. the equipment has good energy saving and environmental protection effect.

The SZL series and DZL series steam boilers developed and produced by ZOZEN boilers are rare environmentally friendly coal-fired boilers under the current environmental protection situation, and fully meet the standards in the non-prohibited combustion zone.

2. the installation period is short and easy to operate.

The SZL series boilers developed by ZOZEN boilers have compact structure, single-layer boiler room, convenient installation and short cycle. The cost is low and the operation is simple.

3. every index of equipment has reached the international advanced level.

SZL series boilers are designed by ZOZEN boilers technicians in combination with advanced technology and experience at home and abroad. Their product technology, performance and environmental protection index have reached the international advanced level.

ZOZEN has references in various industry all over the world. In past 10 years, over 12850 customer cases have been achieved.

Please feel free to fill in the following form or email us (lexie@zozen) to get product information,price,service and other supports.We will reply to you within 24 hours as soon as possible.Thank You!

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price

Copyright: China Wuxi Zozen Boiler Co., Ltd.All rights reserved